Empowering the Future of Food Processing.

Helping food processors gain a competitive edge by revolutionizing operations with AI-powered machines and software.

ABOUT US

Who we are: Our story and mission

The food industry is evolving — and we’re here to accelerate that change. Our company was founded to transform the way food processors handle meat, poultry, and fish by combining intelligent machinery with cutting-edge software.

What began as a collaboration between engineers, process experts, and mathematicians has grown into a multidisciplinary team committed to one goal: helping food processors achieve better performance through smarter technology.

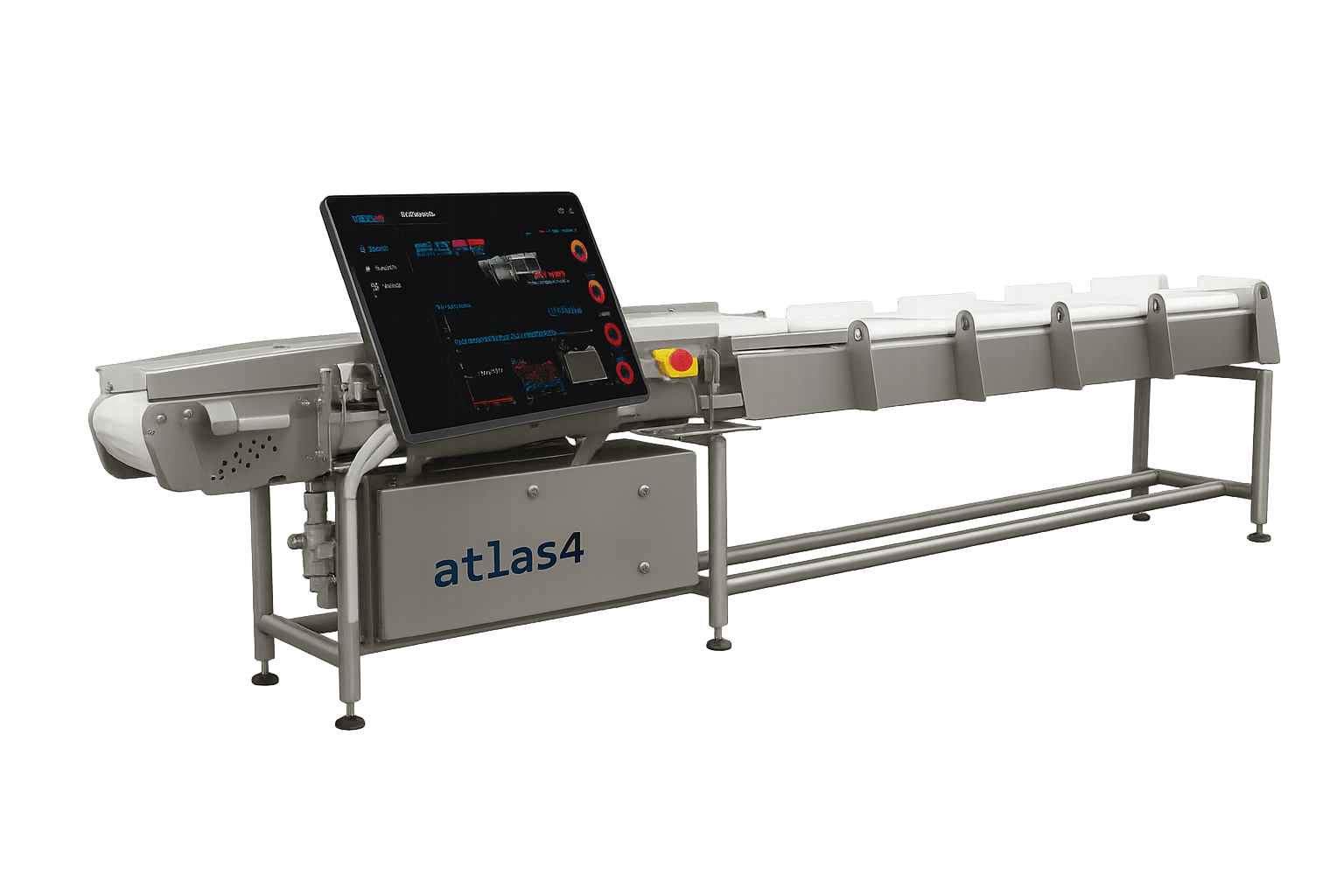

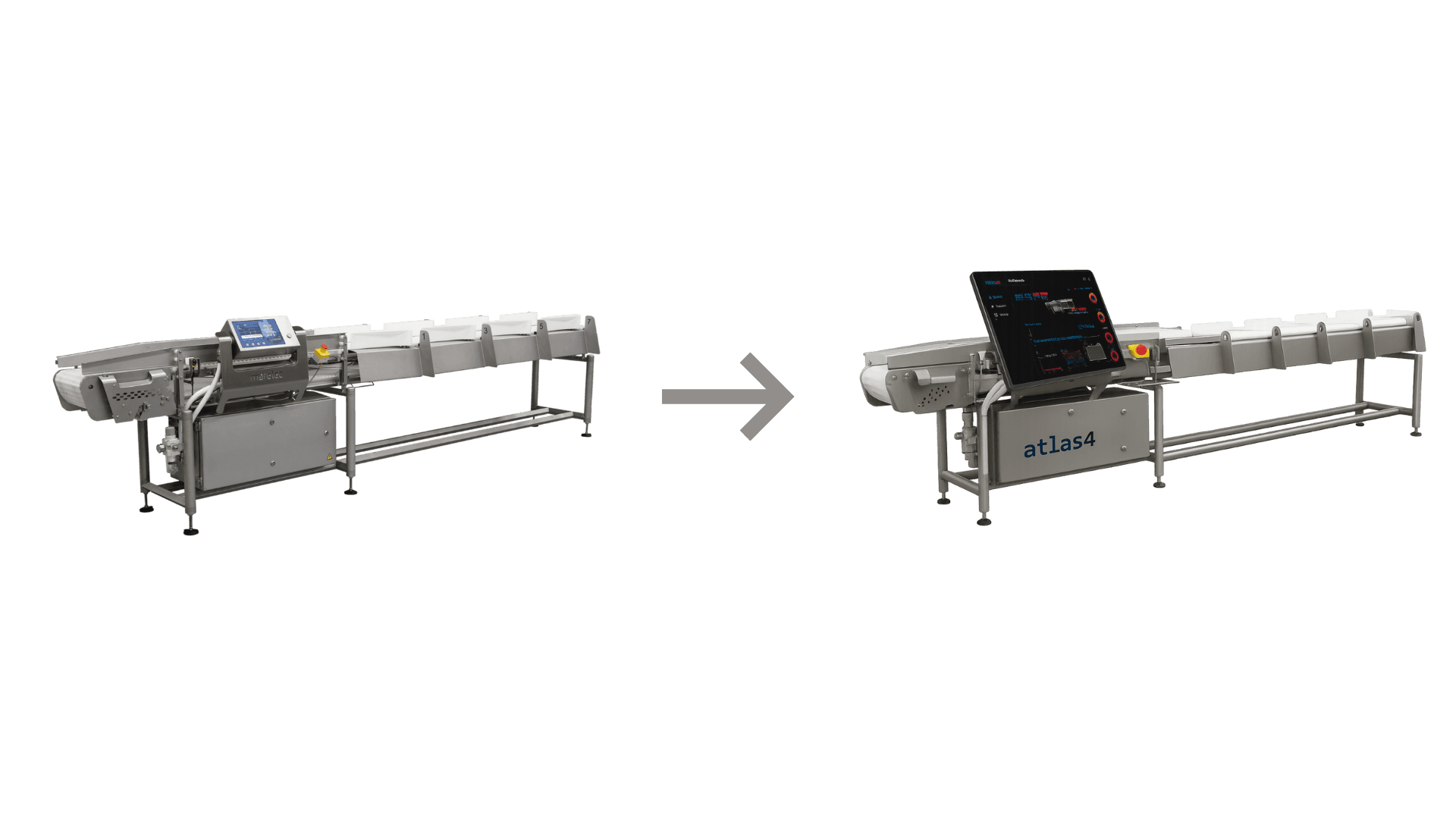

We build both complete AI-powered machines and retrofit upgrades that outperform traditional systems. By replacing outdated rules with adaptive, real-time decision-making, our solutions reduce waste, increase output, and eliminate the need for constant manual intervention.

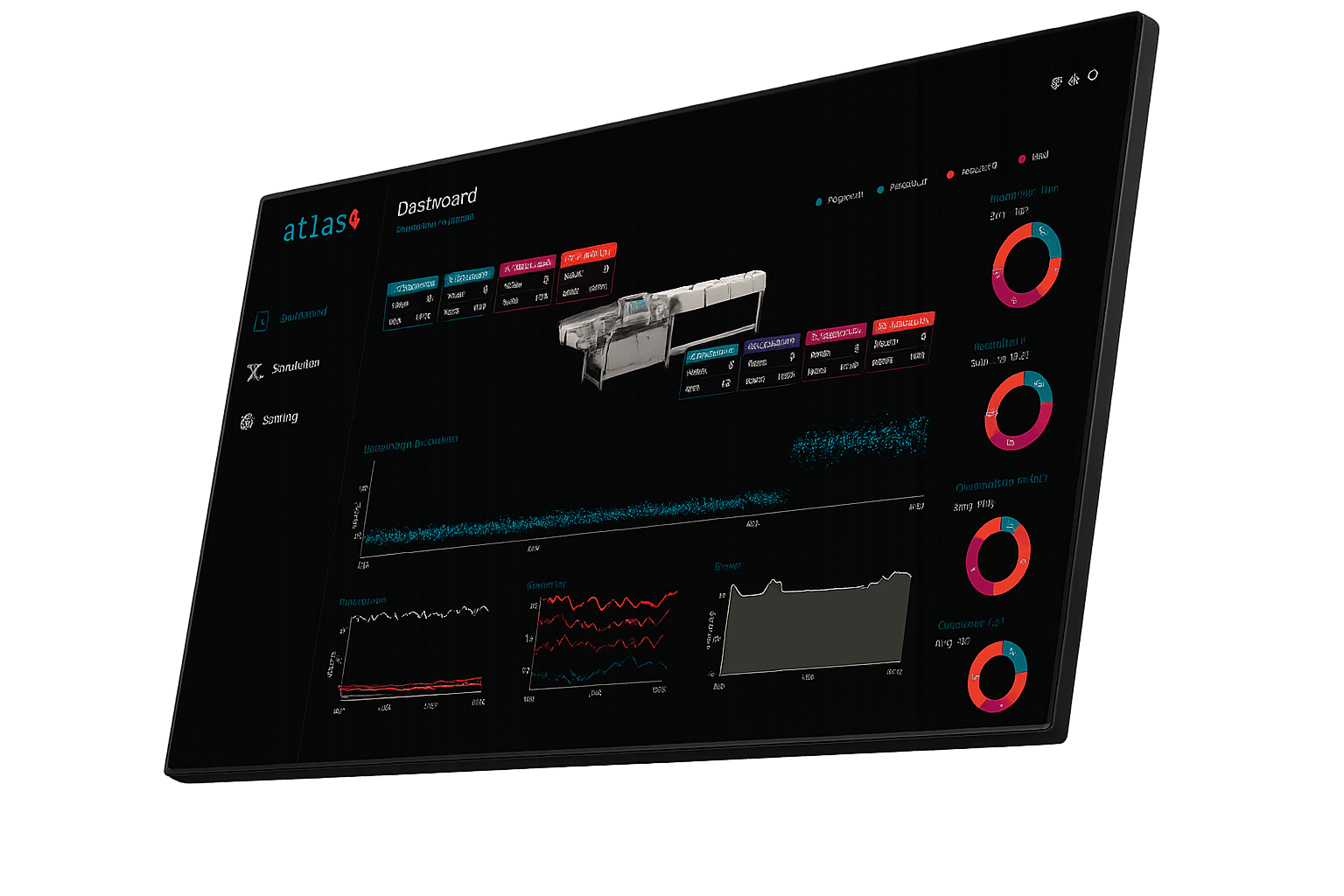

With advanced control systems, AI-driven batching, smart scheduling, and intuitive interfaces, our intelligent solutions help food processors get more out of every product — reducing waste, increasing yield, unlocking greater efficiency, and operating more sustainably.

PARTNERSHIP & CERTIFICATION

Our partnerships and certifications reflect the trust leading food processors place in our technology and team. Together, we work to elevate performance, streamline operations, and drive long-term value and sustainability.

EXPERTISE

What we deliver: Our core strengths

PROCESS

From Insight to Impact — Our Proven Path to Smarter Performance

1 WEEK

Discovery Phase

In this initial phase, we analyze the current processes in detail. Using advanced simulation software, we evaluate your real production data to forecast achievable gains in giveaway, throughput, and yield — with full transparency.

Analyze current process performance

Simulate improvements with high accuracy

Submit your data and receive a personalized improvement analysis:

1 WEEK

[Optional]

Conversion Phase

If an upgrade to an existing machine is chosen, we’ll define all conversion needs and ensure a seamless transition plan.

Assess hardware and software requirements

Create a step-by-step conversion roadmap

2 WEEKS

Installation Phase

We perform the full installation — either of a new BatchMind system or a retrofit (BatchMind Lite) conversion — and ensure all components are integrated, tested, and ready.

Install precision conveyor weighing system

Set up industrial Edge PC with AI-driven batching

Mount and configure the modern AI-powered HMI

1 MONTH

Monitoring/Support Phase

Post-installation, we stay closely involved to ensure success. We monitor performance, fine-tune algorithms if needed, and support your operators on site.

Monitor machine performance and yield

Resolve issues and deploy updates

Train operators and technical staff

PRICING

We offer flexible pricing packages to suit the needs and budgets of all sizes

CONTACT US